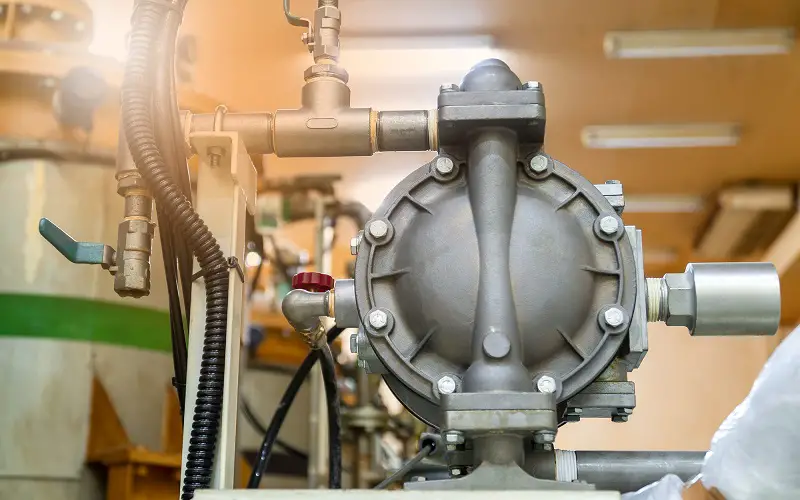

Diaphragm pumps, known as membrane pumps, are types of pumps that can transfer and handle a wide array of media – from clean, low-viscosity fluids to corrosive, abrasive, and high-viscosity substances.

These pumps are made of selected materials compatible with the type of fluid it’ll come into contact with. For instance, if the pump handles potentially explosive liquids, explosion proof diaphragm pump is suitable for that. These types of pumps were designed to operate safely in environments with potentially explosive atmospheres.

Diaphragm pumps are versatile, but they need to be maintained regularly to ensure they work well. This article gives tips on how to keep diaphragm pumps running smoothly and safely.

1. Regular Inspection And Cleaning

Regular inspections of diaphragm pumps can help identify issues before they escalate into major problems. Depending on the type of fluid the pump handles, the accumulation of solid particles in the pump chamber can happen over time. This buildup on the pump’s components increases wear and tear and decreases pump efficiency, leading to potential premature failure.

Scheduled cleaning can prevent the accumulation of debris and guarantees that the pumps work efficiently. With regular inspection and cleaning, you can spot these issues and properly clean the pump’s components that have accumulated debris.

2. Regular Replacement Of Worn Components

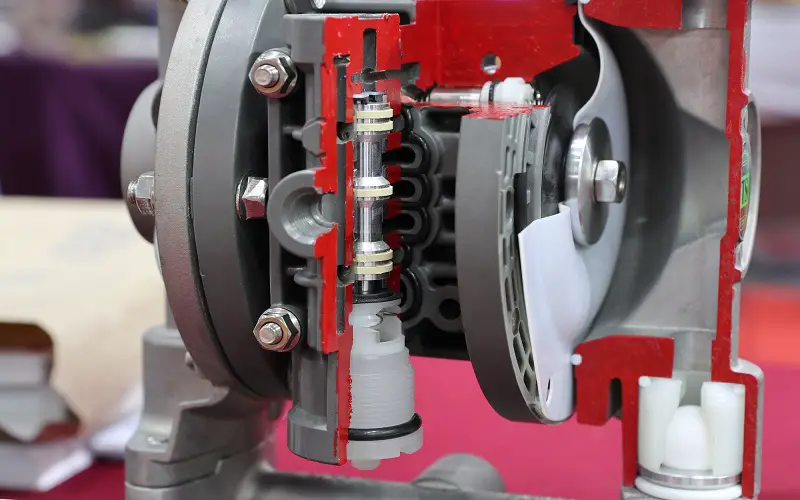

With repeated use, it’s inevitable for some components of the pumps to be worn over time. It’s essential to check and replace worn parts, such as valves, seals, and the diaphragm, to ensure it continues operating at peak efficiency.

For instance, checking the diaphragm for signs of wear and tear, such as cracks, leaks, or deformations, can prevent costly repairs and unplanned downtime. Replacement guarantees that the parts are in optimal condition and perform tasks effectively.

3. Proper Lubrication

Proper lubrication is another crucial aspect of maintaining a diaphragm pump. Regular lubrication of moving parts, such as the drive shaft and bearings, is essential to ensure they move smoothly, function efficiently, and minimize wear.

Having a regular schedule for lubrication can help extend and utilize the pump’s life. Furthermore, adhering to the manufacturer’s recommended type of lubricant for your diaphragm pump is critical.

4. Monitor And Control Pump Speed

Operating the diaphragm pumps within the manufacturer’s recommended parameters ensures efficiency and effectiveness of usage.

Excessive speeds can decrease the pump’s efficiency and result in component failure. On the other hand, slower speeds reduce the risk of cavitation, which can cause significant damage to the pump’s valve, bearings, and other parts.

Monitoring and controlling the pump’s speed can boost the performance and ensure it operates well without compromising the components, contributing to better performance and longevity.

5. Use Of Genuine Spare Parts

Using non-genuine parts to cut costs can be tempting. However, this practice can negatively affect the performance and potentially damage the pump.

Genuine spare parts are designed to work together seamlessly, leading to improved performance of your pumps. They’re made using the same specifications as the original parts and rigorously tested to ensure they meet or exceed the manufacturer’s standards.

Genuine spare parts are made from high-quality materials to withstand the rigors of everyday use. As a result, you can expect your pumps to last longer and require fewer repairs.

6. Regular Performance Monitoring

Understanding your pump’s performance is crucial cause you’ll never know when it may break down. Regular performance monitoring involves measuring and tracking parameters such as flow rate, pressure, power consumption, and pump speed.

Performance monitoring allows you to notice performance drops, helps you take preventative measures, minimizes downtime, and maximizes pump productivity.

7. Training Of Personnel

Proper training for those who operate and maintain diaphragm pumps is essential. These individuals will have the most hands-on experience with the pump, so it’s crucial to ensure they’re trained to identify potential issues, handle the equipment correctly, and perform necessary maintenance tasks. A good training provider can help your team develop the knowledge and skills they need to use the pumps efficiently and effectively.

Conclusion:

The performance of your diaphragm pumps is determined by how frequently you perform maintenance tasks. This article has mentioned some of the maintenance procedures you can do to keep the pump in top condition.

Regular inspection, cleaning, replacement of worn components, and monitoring of the pump’s performance guarantees that each part works efficiently and effectively. This also helps you take preventive measures to avoid further damage.

By implementing these maintenance strategies, you can maximize pump productivity, minimize downtime, and achieve long-term success with your diaphragm pumps.